Software Part:

Here is my kermit config(put it in ~/.kermrc).(other UART software should work too)

(to get kermit into mac, please install macport then call sudo port install kermit)

set line /dev/tty.usbserial

define sz !sz \%0 > /dev/tty.usbserial < /dev/tty.usbserial

set speed 57600

set carrier-watch off

set prefixing all

set parity none

set stop-bits 1

set modem none

set file type bin

set file name lit

set flow-control none

set prompt “MacOS Kermit> ”

Let me explain this:

57600, 8, n, 1, those are the most important parameters.

set line /dev/tty.usbserial

USB-TTL driver position.

set speed 57600

default speed is 57600.

set parity none

8n1, n is this one.

set stop-bits 1

8n1, 1 is this one.

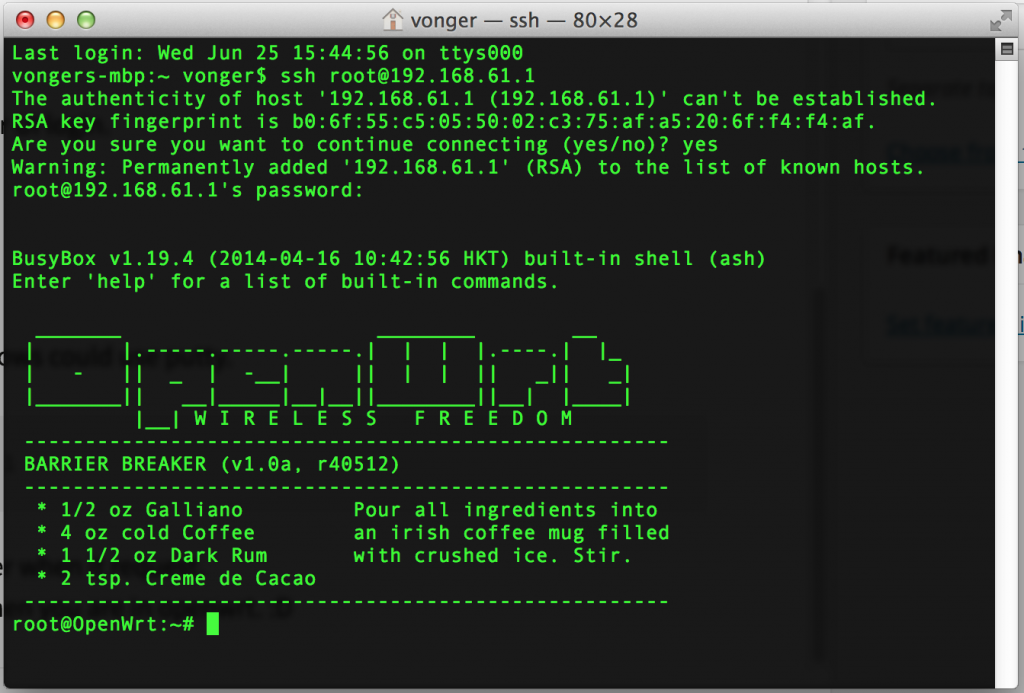

Then, use kermit -c to connect to the UART.

Upload firmware through UART.

There are two ways to download(press ‘x’ once VoCore is booted):

1. tftp

2. uart(loadb then jump out kermit console to send the file)

After load the bin file, then erase linux part by command

erase linux

Final, copy bin to flash.

cp.linux 2c0004

2c0004 is the size of my bin file, change to yours.

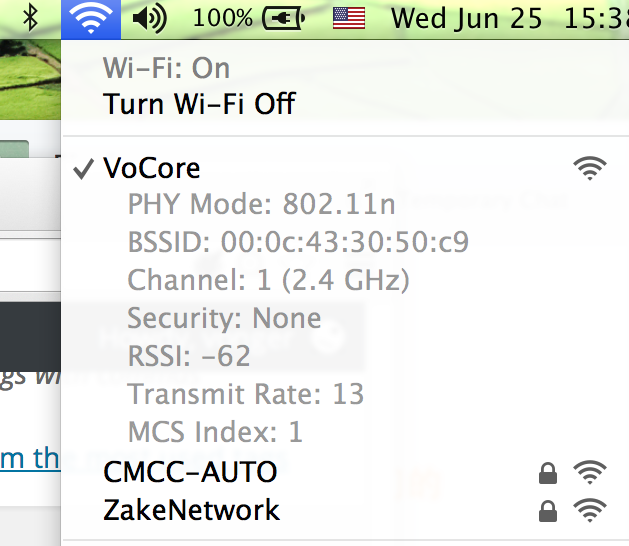

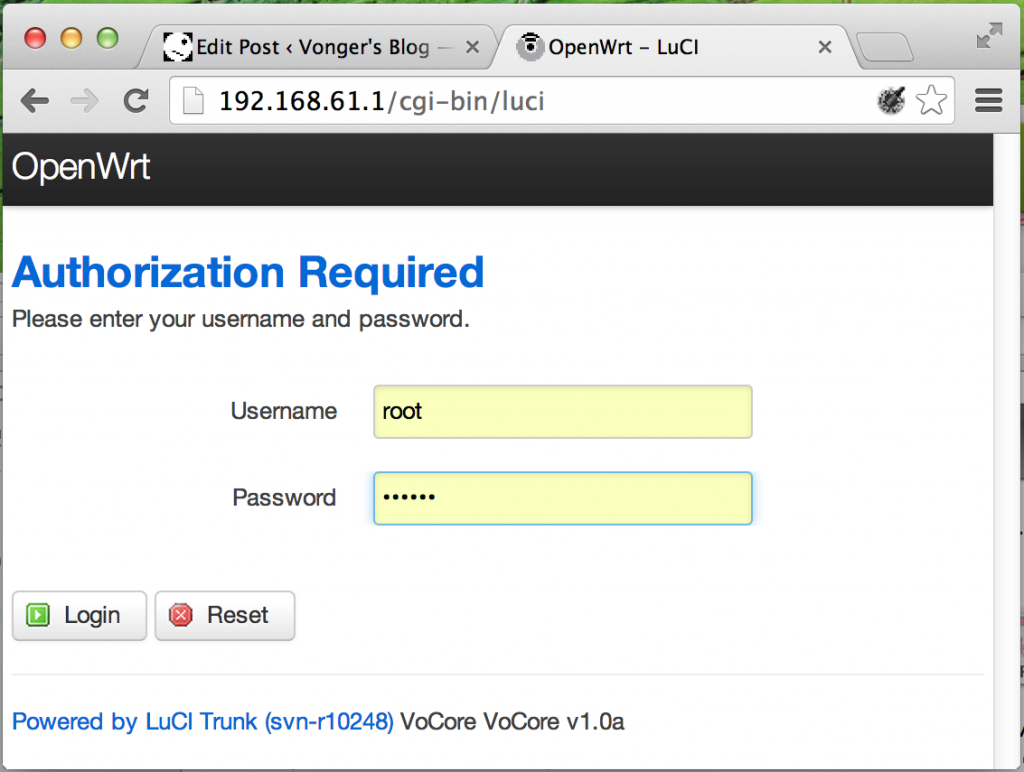

I highly recommend to use mtd through wifi, that is much faster.

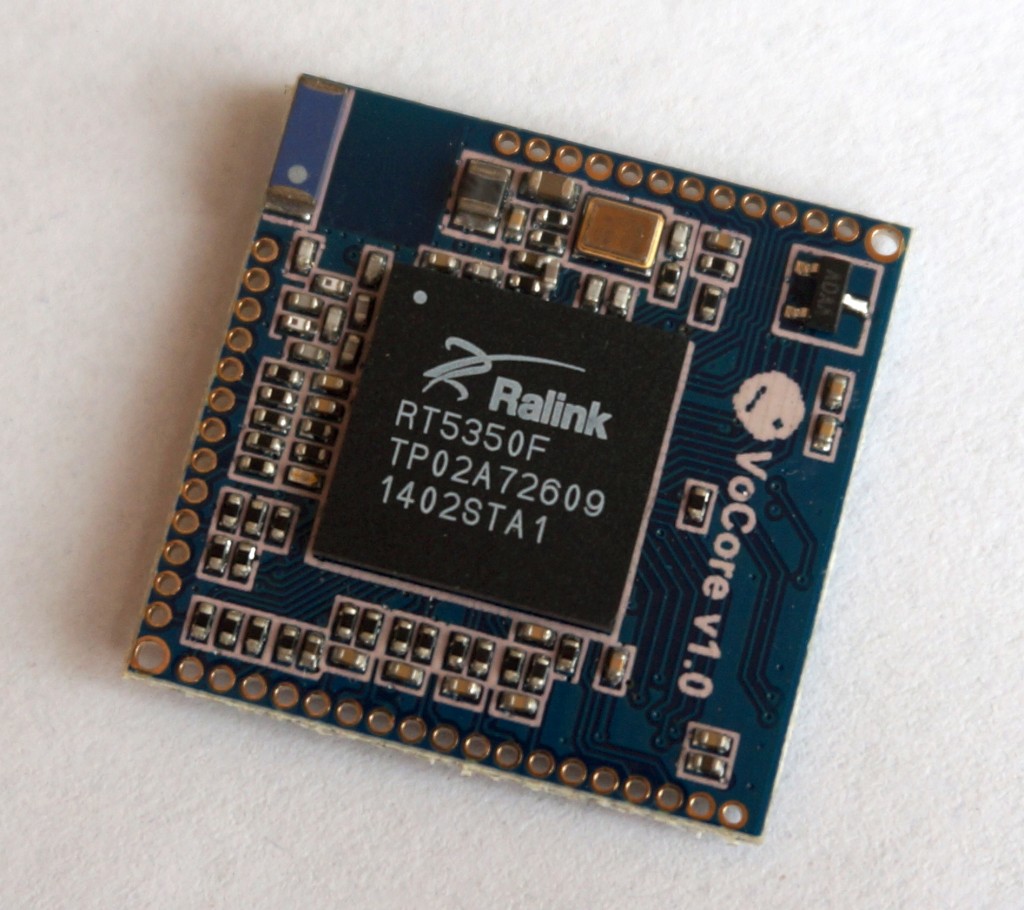

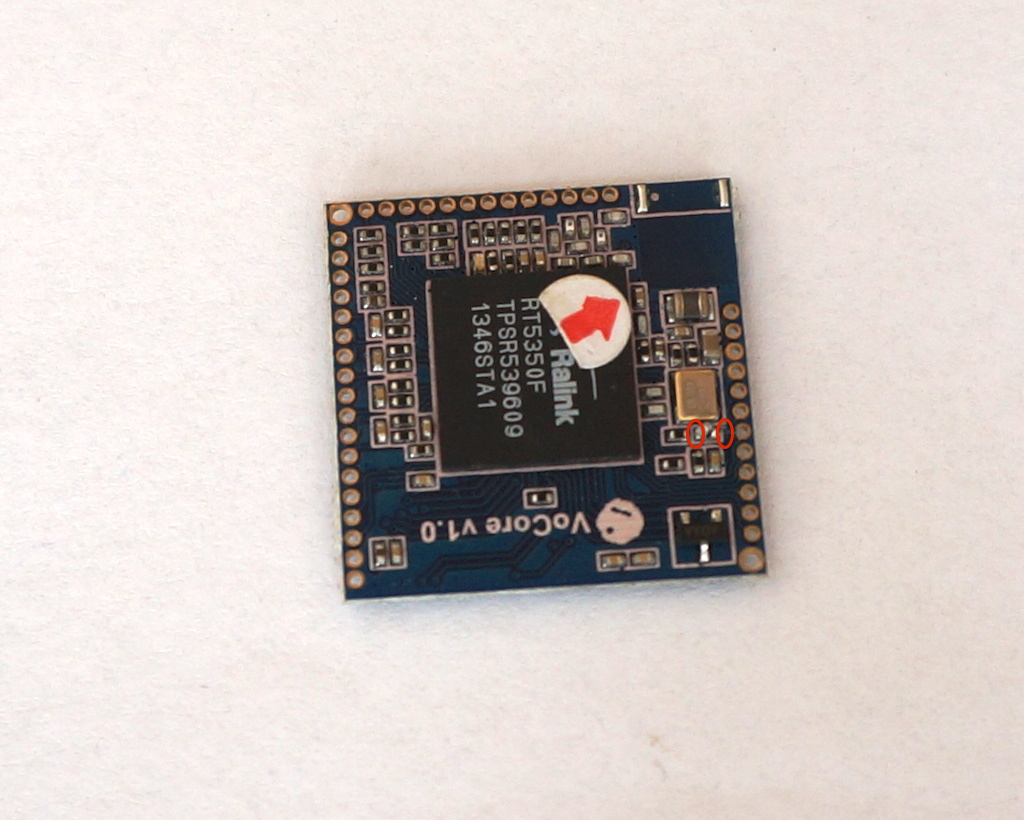

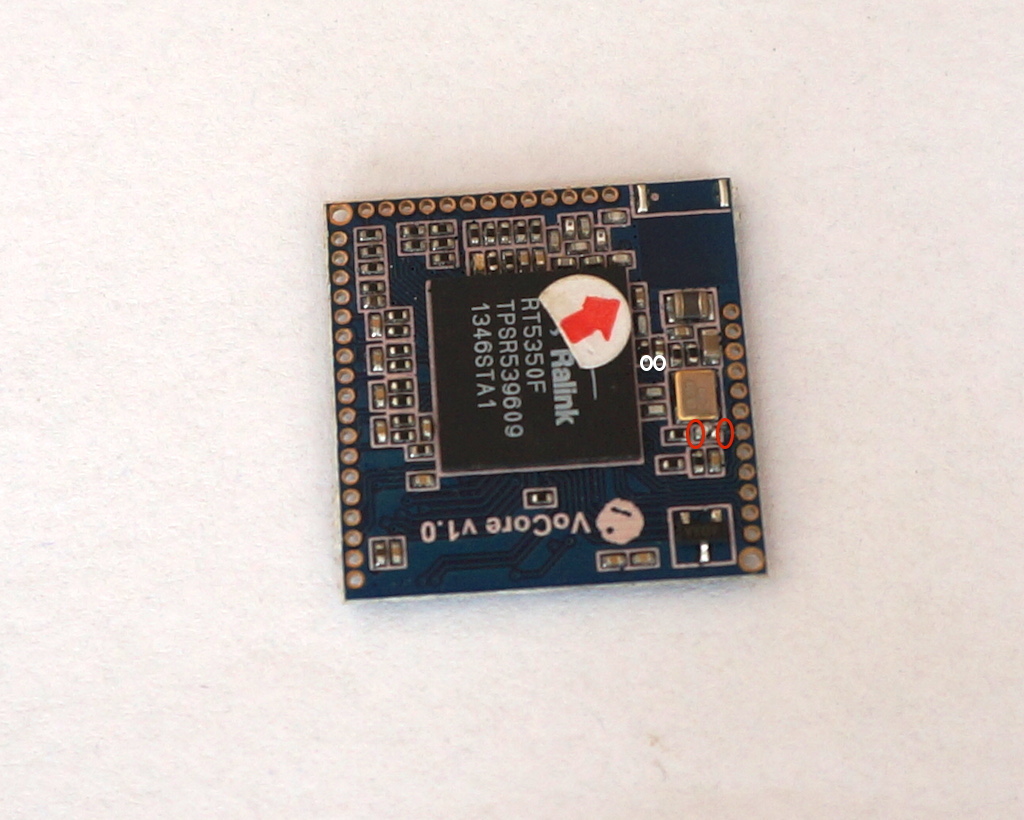

Hardware Part:

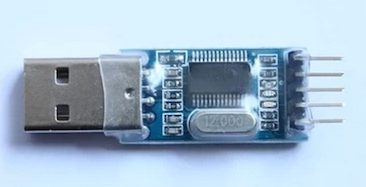

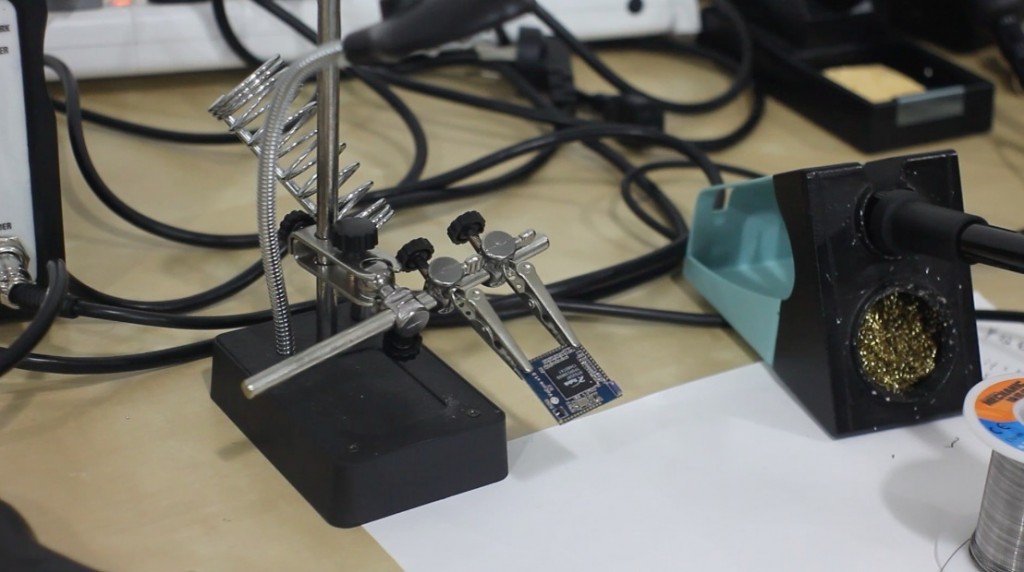

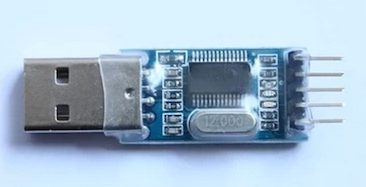

Need one USB-TTL:

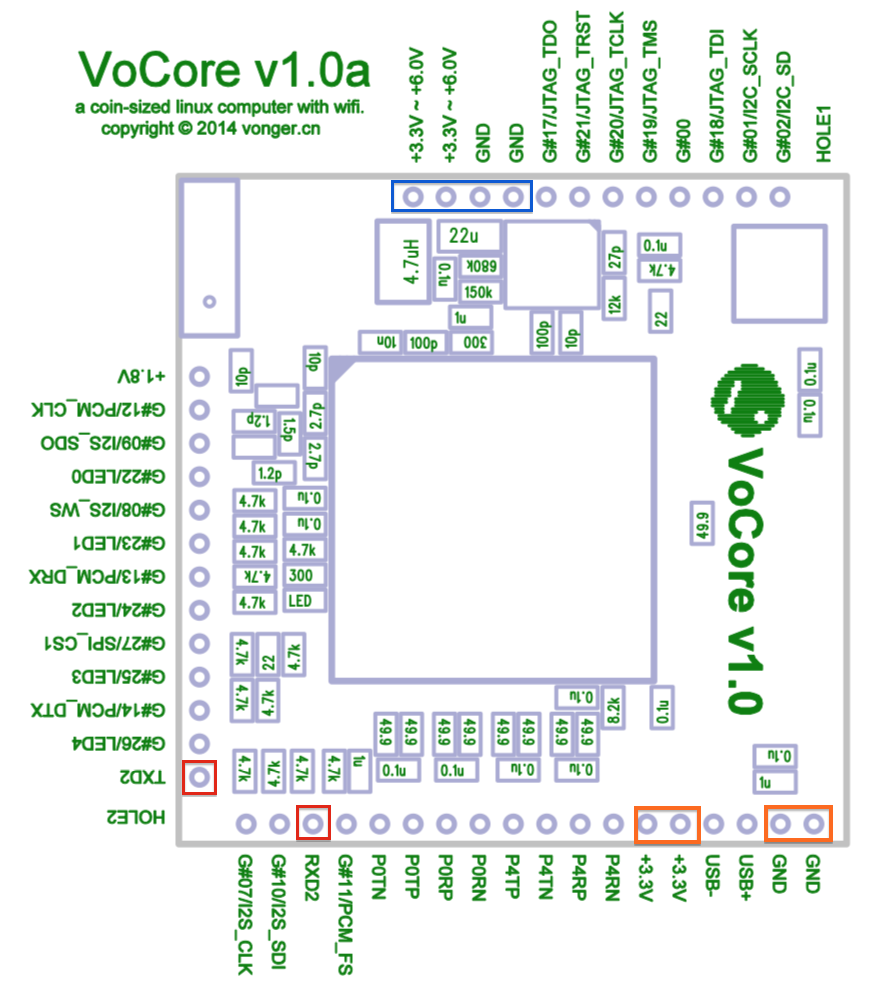

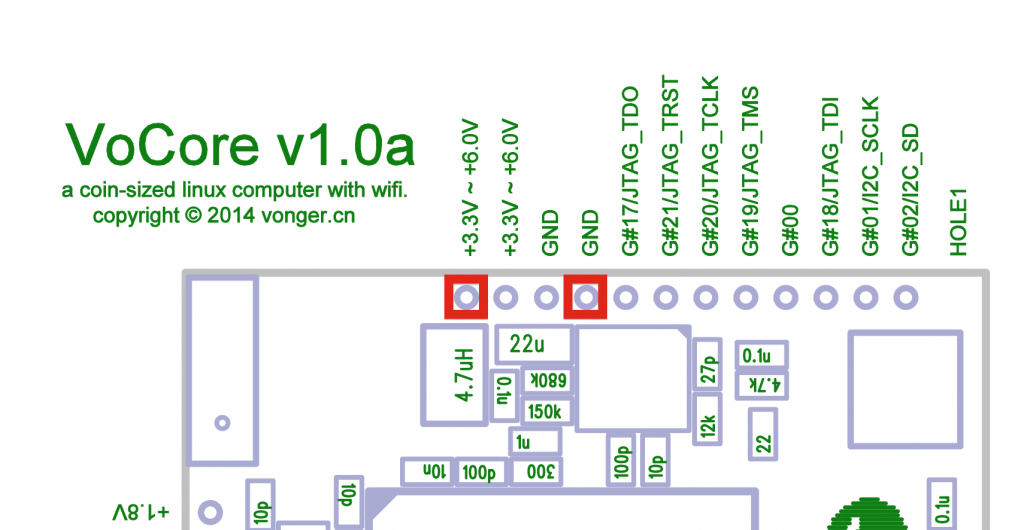

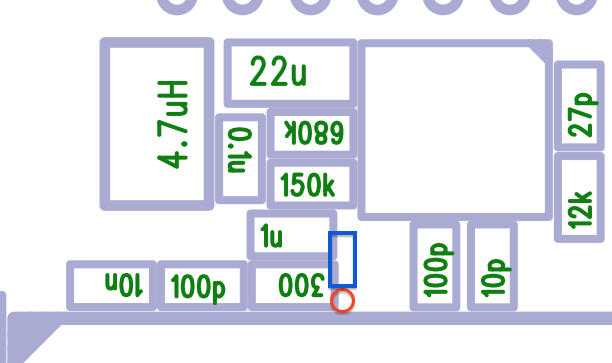

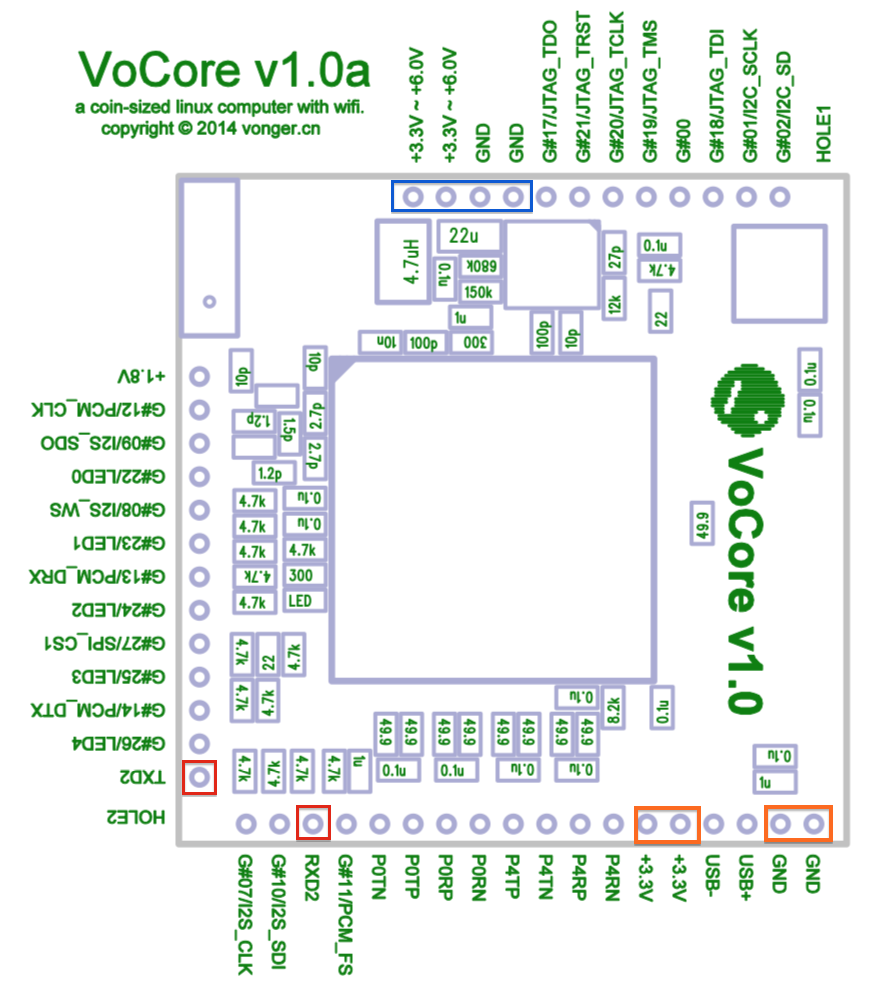

USB-TTL needs three pins(the red part of the following picture) to connect to VoCore.

VoCore.RXD2 => USB_TTL.TXD

VoCore.TXD2 => USB_TTL.RXD

VoCore.GND/Power.GND => USB_TTL.GND

(do not forget connect their GND together, or there will be a lot of garbled text)

WARNING: this is alpha board pin map, release version pin map please read the datasheet on vocore.io/wiki Introduce part.

WARNING: this is alpha board pin map, release version pin map please read the datasheet on vocore.io/wiki Introduce part.

The blue part is the power pin.

It allows 3.3V~6.0V power input, my suggestion is to use 3.6V~5.4V due to input power is converted by DCDC. If you use 3.3V input, please directly connect to 3.3V at the orange part.

The orange part 3.3V can be use as

a. Output: if you connect power to 3.3V~6.0V pin.

b. Input: if you connect 3.2~3.4V power to it.

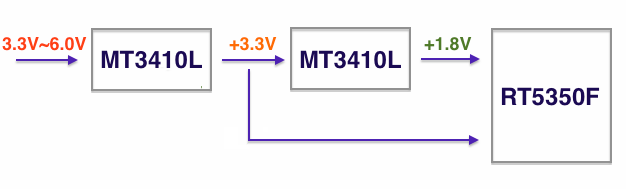

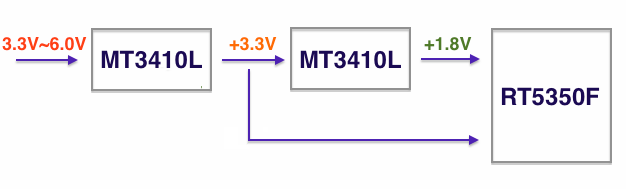

power 3.3V~6.0V input is convert to 3.3V then to the chip.

Like this:

My compiled Kermit: http://vonger.cn/upload/tools/kermit