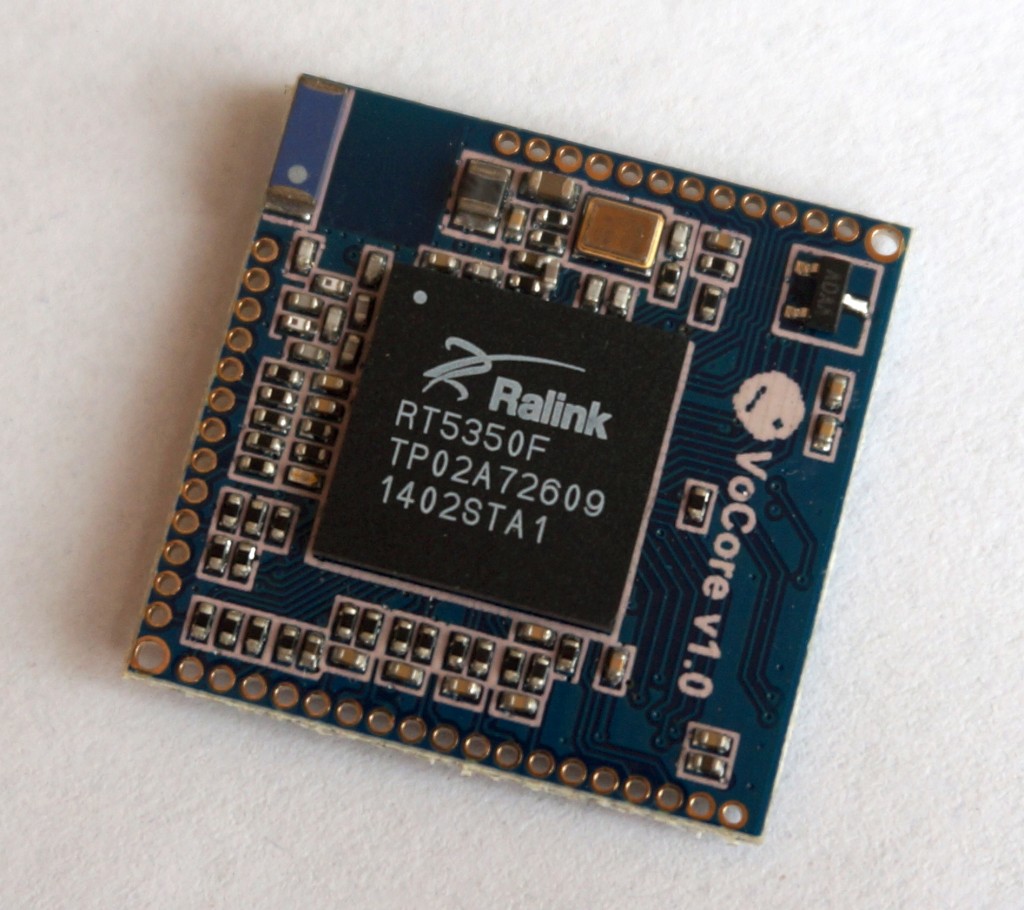

First: this one is fixed one:

Plan A: Simple Tools(need high skill):

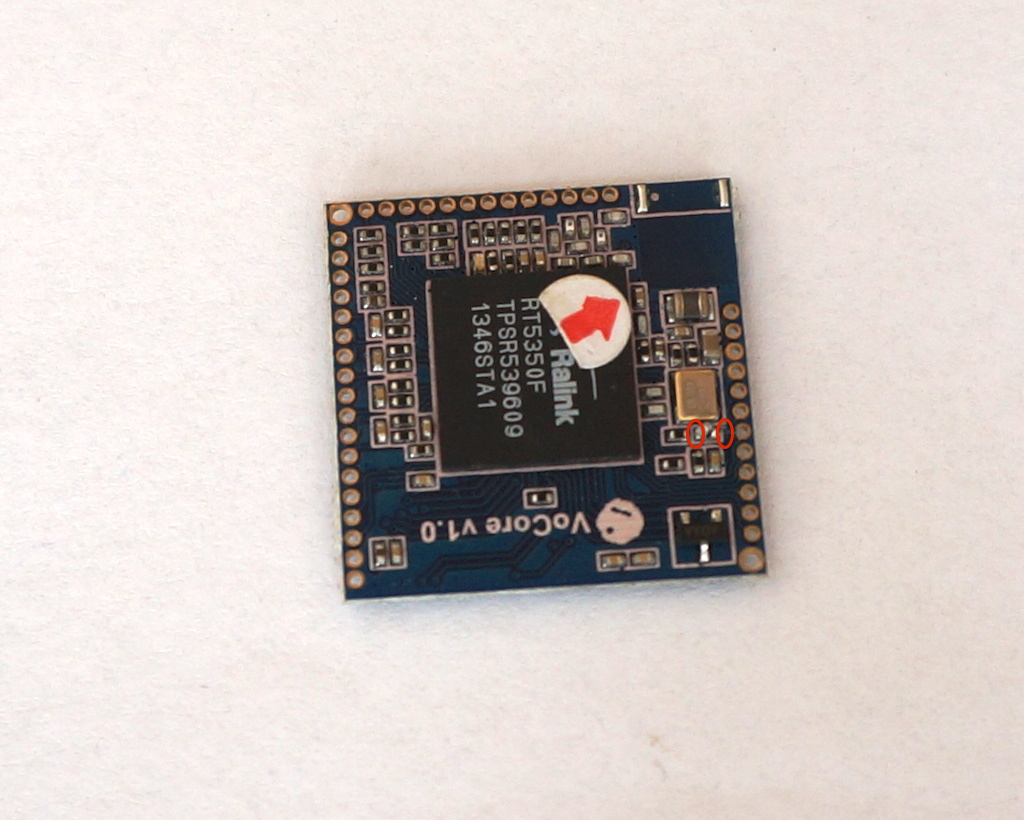

Step 1 => take off the old 27pF cap.

I am using Ag-Sn, 221C melt down(Ag-Sn-Cu is another choice). And 180C Pb-Sn or Ag-Bi-Sn should be OK too.

Use the tweezer bit that 27pF cap, then use your iron(better to be 280~300C) touch the one red point, about 1 second, move to another red point for 1 second, do this again and again… until the paste is melted.(my iron is not good, only 250C, it takes about 2min) Then your tweezer will get the cap.

Step 2 => solder 27pF cap onto the position.

We need to cut off some Ag-Sn from the Ag-Sn bunch.

Use iron to melt them into two about 0.3mm Ag-Sn metal ball.

The ball can not be too big, or it will be easy to cause short connect, and once it is short connected, it is very hard to fix.

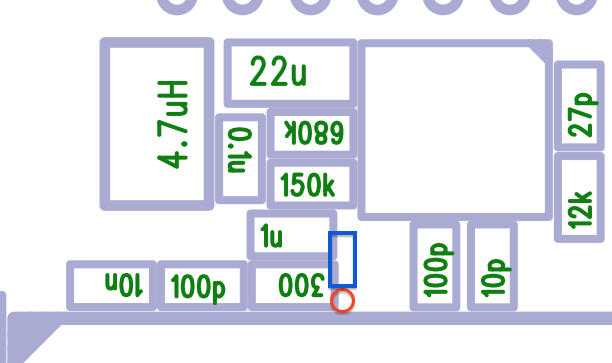

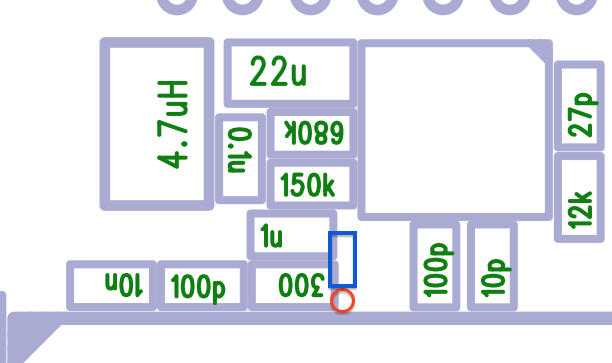

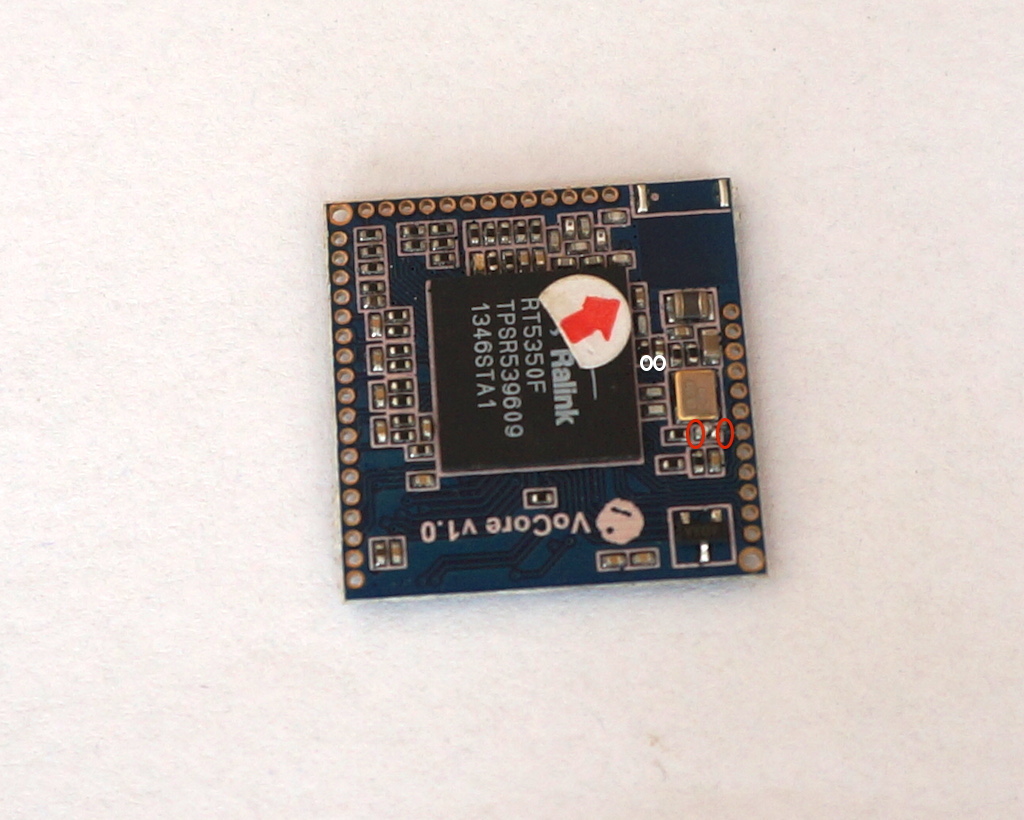

There are two white point.

Put a little flux onto the white cycle, the put one little Ag-Sn ball to one white cycle(the flux is used to keep the ball touch the PCB and not roll to everywhere.)

Put the 0402 cap beside that ball. Like this:

Use your iron melt that ball, so one side of the 27pF is connected to 300ohm(or 1uF)

Then put other ball between another white cycle and another side of 27pF, use the iron melt down that ball. Now the 27pF should be well connected with the two white point.

Plan B: Hot air + Ag-Sn-Cu Paste(about 226C) (very easy)

Step 1 => Make hot air to 280C~300C, target to that 27pF, about 30second, use tweezer take it off.

Step 2 => Put 27pF onto the position(blue rectangle).

Use your tweezer get a little paste, and put some to the white cycle.(do not put too much or it will short connected). Then put 27pF on the paste.

Hot air again, melt down that paste, it is connect perfectly.