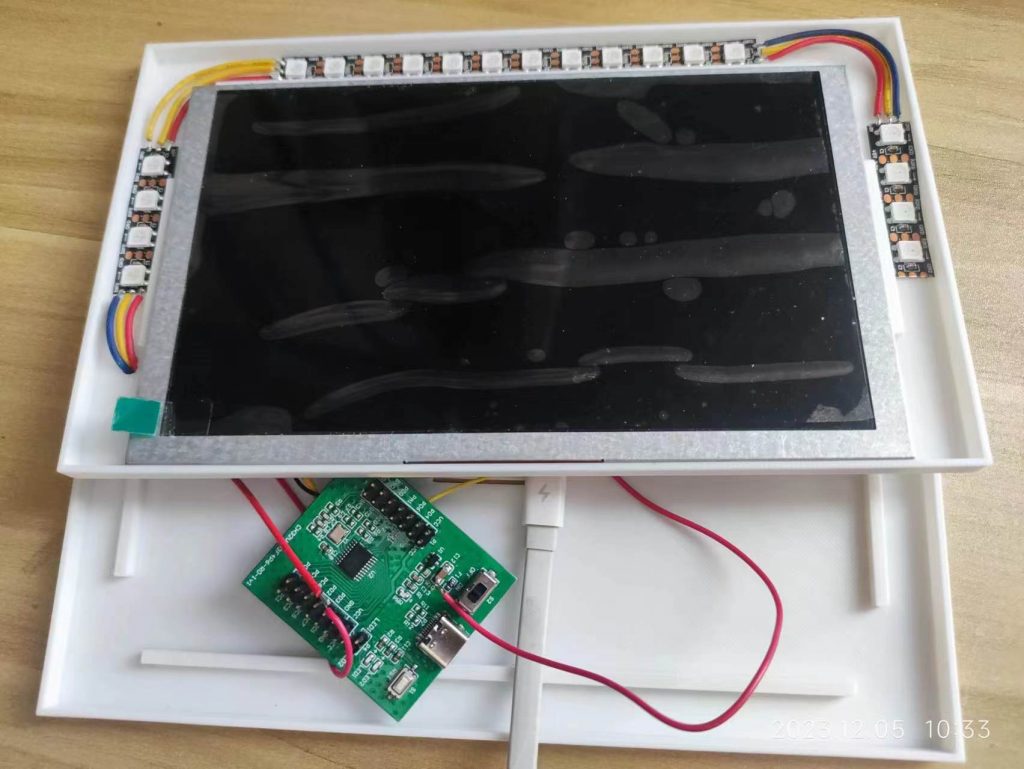

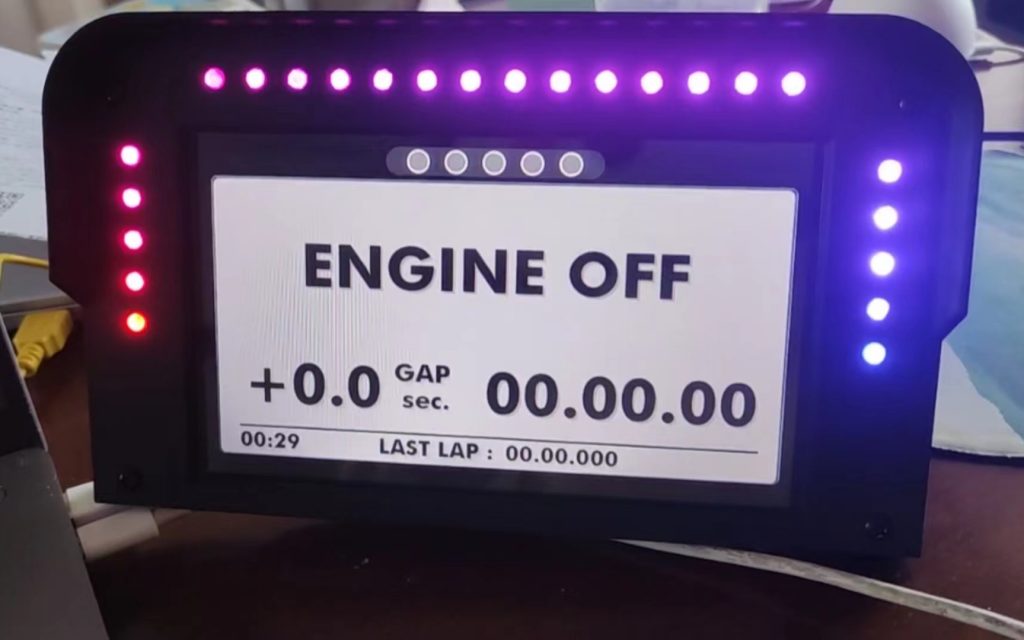

In order to simplify the development of dashboards based on the VoCore MPRO screen, CH32V003, and WS2812, we have created a simple demo that is now available for order at vocore.io/store.

The shell was designed using FreeCAD. We are not experts in design, so please feel free to modify it. 🙂

Download here https://github.com/vonger/6IN8SHELL

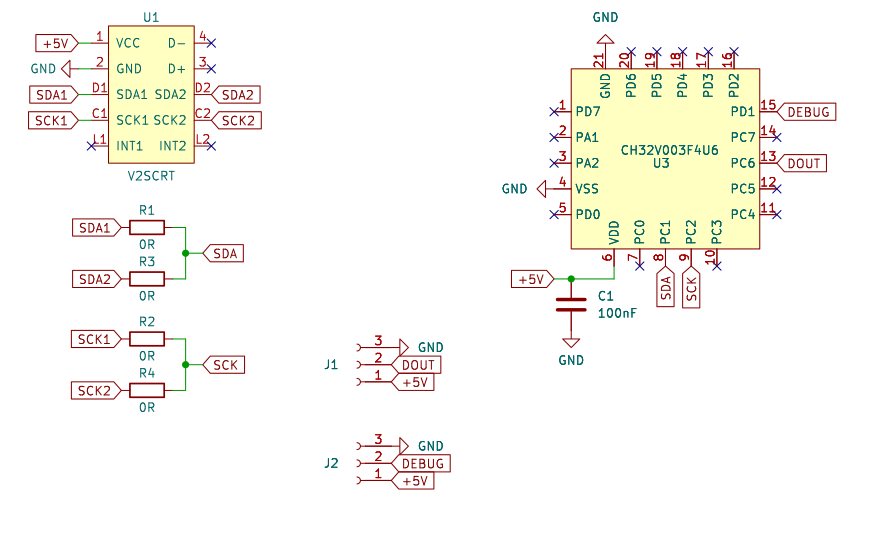

Reference link: https://github.com/Vonger/V7B_WS2812B

Reference link: https://vonger.cn/?p=15457

Note: This demo is designed to show how MPRO works with WS2812 LEDs. I am not skilled in design, so it is not recommended for DDU users. However, if you wish to use it as a low-cost DDU, I cannot stop you. 🙂

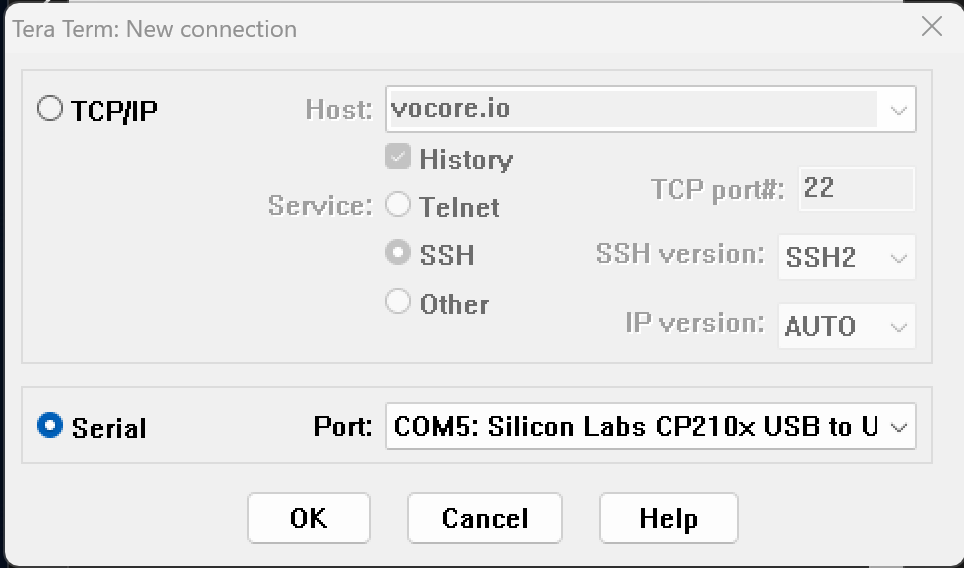

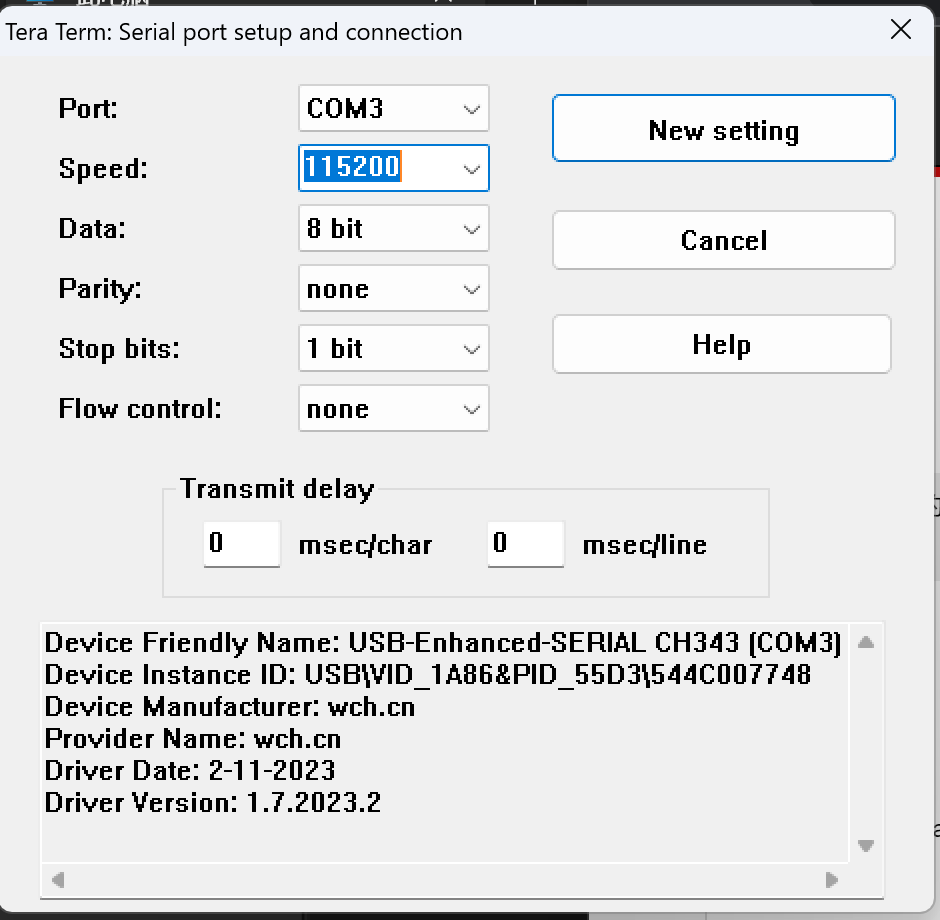

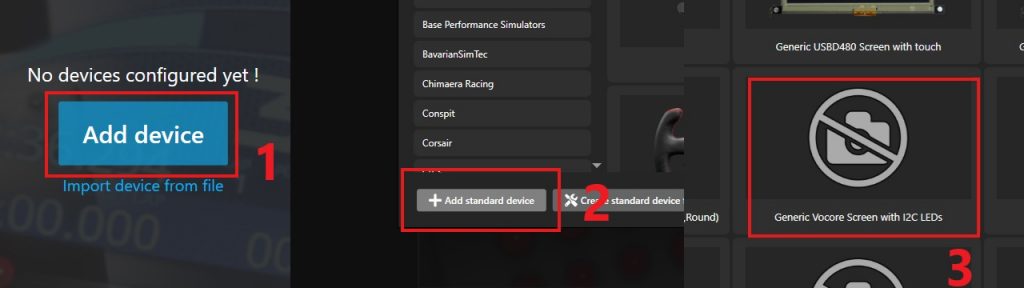

Setup in Simhub: Devices => Add new device => Create standard device => Generic VoCore Screen with I2C LEDs

Note: if you have exists arduino LED profile, export then import to Generic VoCore Screen with I2C LEDs, it will work.