Recently I get around 10pcs broken ones returned. Is it really the mystery ESD problem or something else? Let’s analyze one by one check what is the problem. Hopefully this blog will also help DIYer find a way to solve such problem.

1.Obvious physics broken ones:

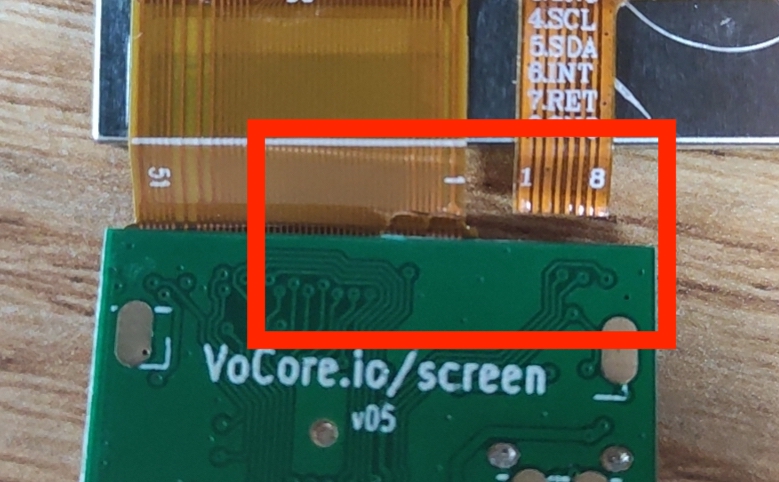

Four screens has such problem. Red rectangle area is the weak point.

Left FPC 51p is for screen and right 8p is for touch screen. From the picture, the 51p and 8p both tear off by force. FPC is something like tape, it is afraid of sharp edge. Such problem normally happens when you bend the FPC hard, and FPC touch the PCB or the connector edge, it will be easily broken.

Recommend: FPC better to have a beautiful round corner, this will reduce tear off chance, also use the bubble tape around 1mm to stick it to PCB or back, NOT recommend use the hot melt adhesive, it is bad to fix the PCB because there are so less margin after it becomes solid, that will cause it easy to broken FPC.

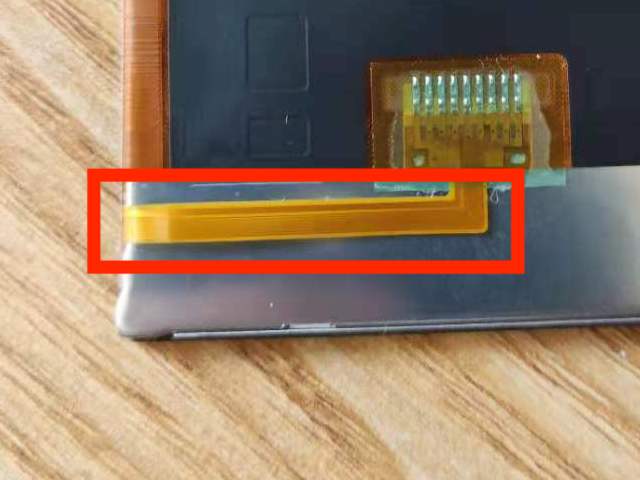

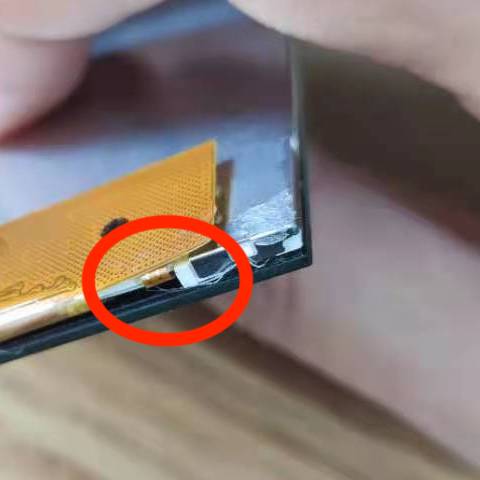

2. Hidden Physics Broken

This screen problem is when we run test application send_frame frame.dat, its backlight will not able to turn on. One of broken screen is such problem. After remove its touch screen, I find the FPC is normal, but the liquid crystal driver chip is shattered. That driver chip is like a very thin glass, and when people is trying to force the glue on FPC off its holder, it will have very high chance to broken that chip.

PS: this part debug is a pain, last year on another project we use this screen, around 20pcs broken because of such problem, workers mistake stick the bubble tape to this area so when we remove the screen to repair other parts the screen broken by the force.

Recommend: tape or adhesive leave far away from this area! Do not touch this FPC at install. New version screen do not have such problem, but we still suggestion do not put any tape or adhesive on the FPC area, it should be only on the steel part.

3. Not Well Connected

One broken because of this reason, this screen also has FPC tear off problem.

Recommend: please do not use adhesive… 🙁

4. Firmware Problem

Rest screens are all such problem. This problem I never expected. That just is the unknown device problem. This should not happen if the screen is operated normally, I guess maybe some client side code has bug, I will check with SimHub developer.

For my MacOS or Linux, we have lsusb command, it will show the device like this:

Bus 020 Device 005: ID 04b4:8613 Cypress Semiconductor Vendor-Specific Device

If firmware is normal, it should be like this:

Bus 020 Device 011: ID c872:1004 c872 USB2.0 Screen

The firmware is written in EEPROM, and it should never lost any data unless client side application write something wrong to it…This is very weird.

I attached the firmware loader(download here), this application only run in MacOS.

For PCB version v05 and v07a, please call

./eeprom w ./FW200502-4IN14V.bin

For PCB version v10a, please call

./eeprom w ./FW210105-4IN3V3

After firmware upload completed, disconnect and reconnect the USB cable, all of the screens has such problem are fixed.

So the final result, none of the driver board are really broken 🙂 Just the physics broken screen we can not fix have to change screen. All 10 of them are repaired.

5. USB cable problem

This is not belong to this part but also very important, please use a short or well covered USB cable. This screen used max USB speed, every data line is 480MHz, so a bad quality USB cable will not make it work, will cause sometimes the screen can not be recognized or show some random noise on the screen. We also think the firmware is broken by this way. This need to be confirm.