Here are some questions from indiegogo private message and comment, hopefully this will help you know more about VoCore.

1. Are there SPI pins export?

Only one is exported, it is SPI_CS1, also can be used as GPIO. Rest SPI pins/balls are not exported because they are already taken by SPI flash. Another reason is there is no space for that hole.:D If you have to use SPI interface, please try to jump wire directly from the SPI flash. Good luck 🙂

2. Can I use Li-Battery as power input?

Yes, of course. Li-Battery is about 3.7V~4.3V, and VoCore allowed input voltage range is 3.3V~6.0V, so USB and Li-Battery are both fine to it. Even four 1.2V AA batteries could do that.

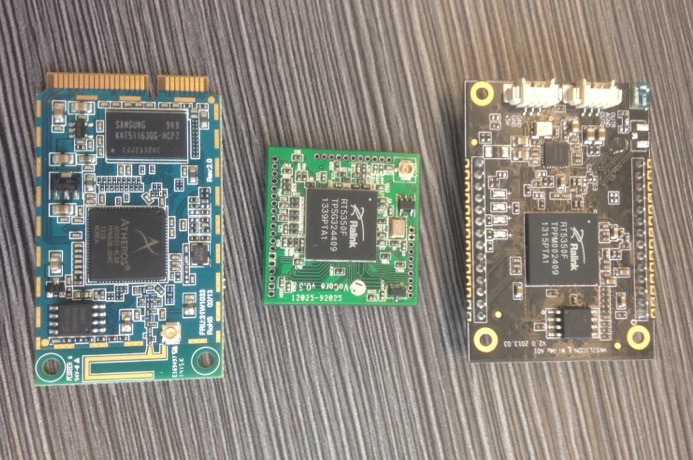

3. Why not use BGA SDRAM to make it smaller?

I think I can make it to about 22×23 once using BGA SDRAM, but BGA SDRAM is so expansive, about 5~6USD for one. And 22×23 compared with 25×25 is not a huge difference. So I choose TSOP54 SDRAM.

4. About the heat of CPU.

It is really hot. From my last test, it works around 63C for about 10 days without any error(my house is about 24C, my power is cut off so the test is end there). The feeling of 63C is very hot that you will not want to touch it. 😀 The dock with metal ethernet connector will be designed as a heat sink. Anyway, I think it should be OK to work at 63C or even more, my friend has used RT5350 to make wifi cameras without any heat sink(just be dropped into a metal box to protect it from rain, as he said) for the traffic monitor on Xi’an street about two years ago, the highest temperature of there in summer noon is over 50C. They are still working. 🙂