Finally, everything is done 🙂

Docks are ready and will transfer to post office in two days.

I have some experience:

1. I heard many bad stories about the quality of “made in ShenZhen”(or made in China), I am a little “scared” before I do it , very carefully to choose the factory. I asked many friends and search,search,search…(I am a Chinese, but be honest, I do not have much confidence.)

But finally, I find most of the stories are not true.

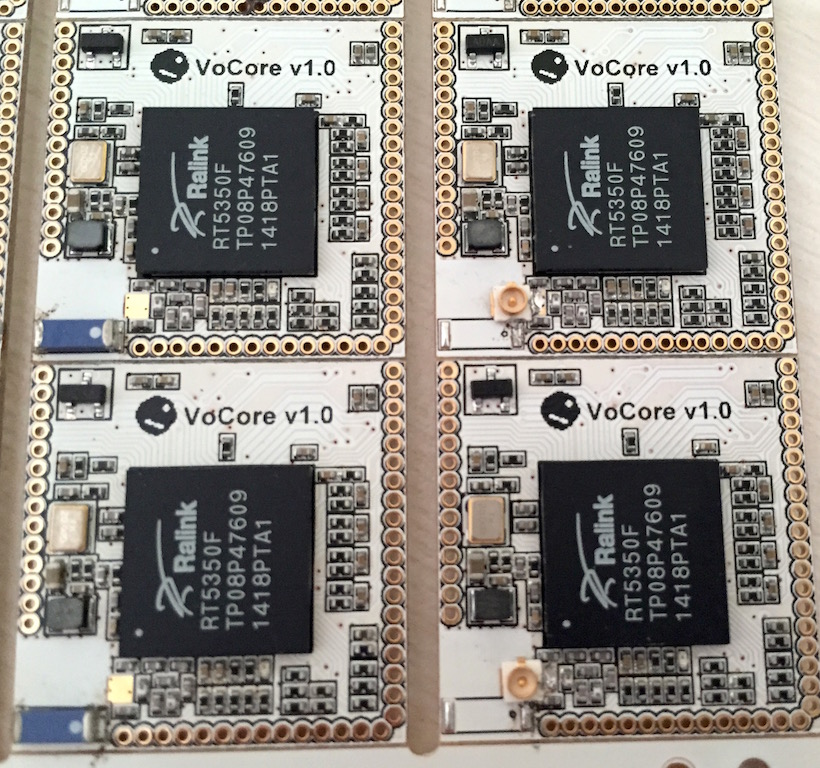

When I talk with the materials provider, they just give me two lists, one is from original factory(always big factory), one with fake on it(from country side, electrical rubbish etc). To get good one, you have to cost twice or even more. They just tell everything and leave the choice to you.

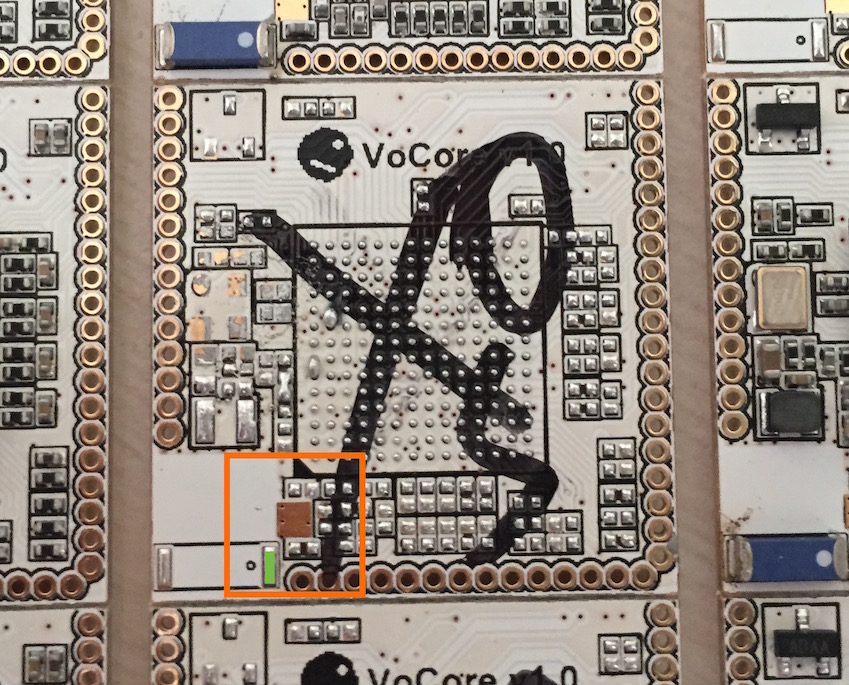

Of course, I choose the good one. The benefit is obvious, VoCore good rate is over 99.9%, rest 0.1% issue is some antennas lost in SMT…So in another word, the good rate is almost 100%( from test. 🙂 )

The higher the price, the better the quality of the merchandise.

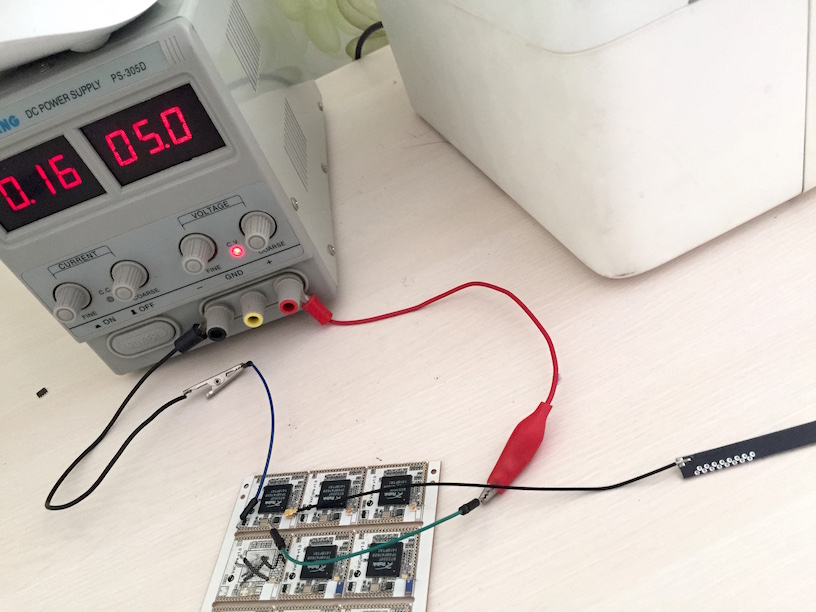

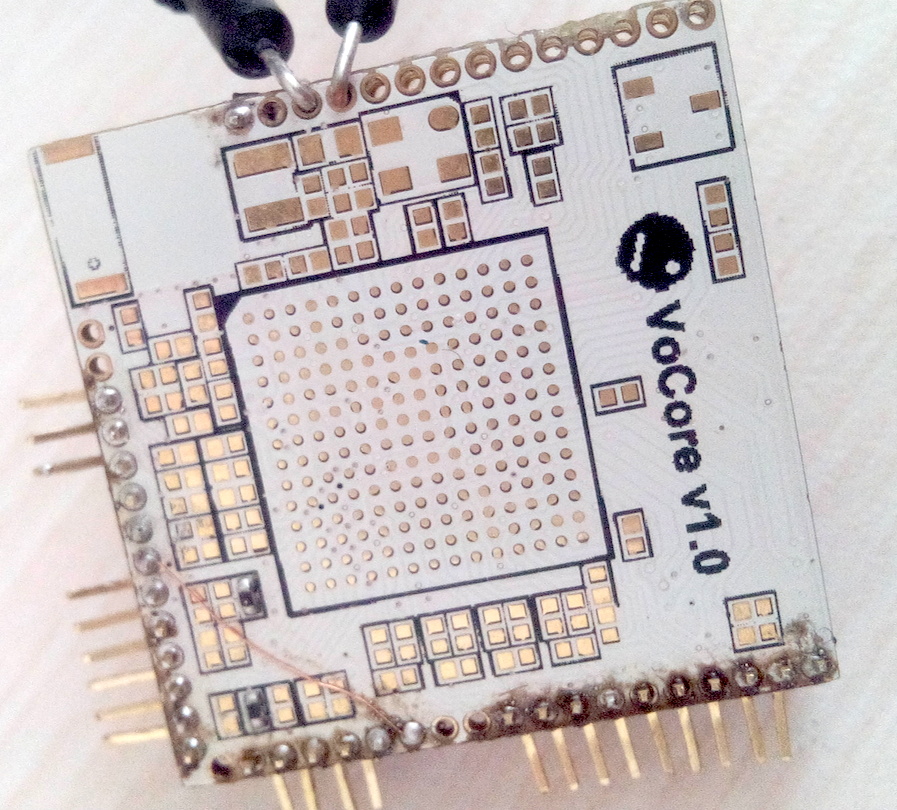

2. Assemble/SMT. There is not much to say, due to 90% work are done by machines, the machines are all from Samsung(their main job is to do work for Samsung Phone/Pad etc), only test part there is a little human work -> put VoCore to the test fixture…They click “Start” on my test application, wait, until the app say “Yes” or “No”.

The factory engineers are very experienced, they help me a lot when I design the test application. I think this is bonus for made in China, most of the production made here, you do not have to cost time and money to design a new test process, but just improve current test process, and get a even better quality.

3. Some suggestions for hardware hobbyists all over the world. If you want to make your production in ShenZhen, better to have a Chinese in your team deal with the factory, some factories have salesman speak English, but engineers do not speak English, if they have problem in the production(this always happen), it will be hard to communicate.

99% of Chinese people are good, if you meet the 1% bad one, you will lose everything. To avoid such problem is easy, just compare, compare, compare…and most important thing, careful if the quote is too low(especially some small factories, their quote is always unbelievable low, 40%~60% as the good quality ones), they use second-hand chip or rubbish chip and you will never know, they can pass your test, even 20% production is NG, they still earn a lot, unless you stay there and monitor them in factory everyday.

Finally, I do not care VoCore is OSHW or not, I do not intent to make it as a “sell” point. I just remember when I was very young, the electrical products are all have schematic in the manual, and my father helped me study the radio…

do not know when that disappeared, just want the happy days back. ^_^